R&D

The Best Power Plant Service Company

용접절차개발

HOME >

R&D >

용접절차개발

HOME >

R&D >

용접절차개발

거명파워는 원자력,화력,복합발전 등 각 발전소에

적용된 소재(Turbine Casing 등)에 대한 보수 용접 절차를

개발 및 보유하고 있습니다.

용접 절차 개발 순서

-

Draft WPS

-

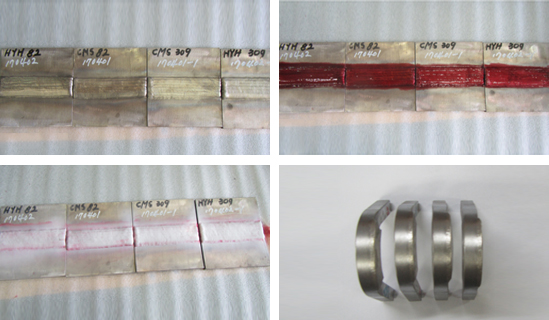

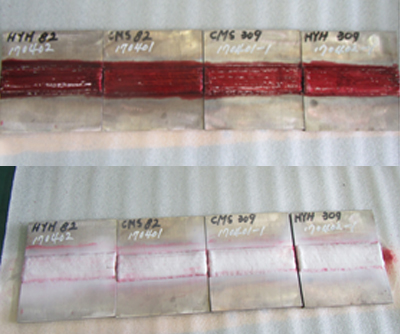

용접시편 제작

-

비파괴 검사

-

굽힘시험

-

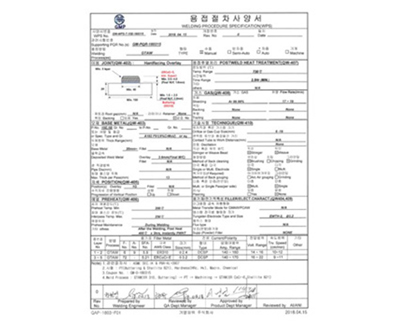

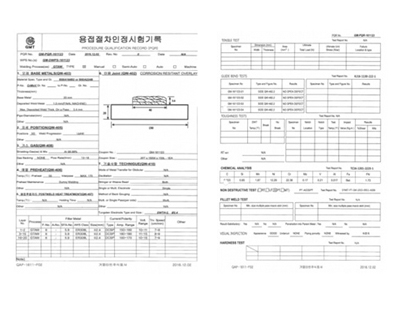

PQR & WPQR 작성

-

WPS 완성

| Base Metal | HP Casing, LP Casing, Packing Casing, BFPT Casing, BFP Casing, Pump Casing, Turbine Diaphragm, Etc. |

|---|---|

| C-Steel (P No.1,3), 0.5Cr-0.5Mo (P No.3), 1.25Cr-0.5Mo (P No.4), 1.25Cr-1Mo (P No.CrMoV), 3.5NiCrMoV (P No.9A, 9B, 9C), STS (P No.6,7,8), 9CrMoVNbCo (P No.7, 15E), 12CrNiMoVNbN (P No.6), Inconel (P No.41~47) | |

| Filler Metal | Alloy #82 (NiCr-3), ER309/309L, ER410, ER70S-2, E7016, E70S-6, E71T-1C, E9016B3, E90SB3, ERCoCr-3, ERCoCr-A |

| Welding Method | GTAW, FCAW, SMAW, Combined |

| Note | - Use for High Quality Filler Metal - Exclude PWHT for Site Application (Temper-Bead Method etc.) |

참고

- PQR : Procedure Qualification Record (절차 인정 기록서)

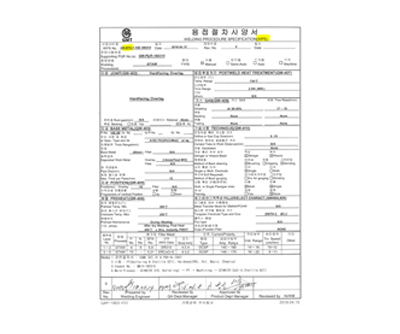

- WPS : Welding Procedure Specification (용접 절차 사양서)

- WPQR : Welding Procedure Qualification Record (용접사 자격 검증 기록서)